RYZ-750A Series Hydraulic Automatic Cup Making Machine

RYZ-750A 全自动液压制杯生产线

A. Functions and Characteristics 功能与特点

RYZ-750 Series of Full-automatic Hydraulic CUP-making Machine developed by our company is a fully automatic plastic container’s forming machine which features in high speed and high efficiency. This machine is applicable to the production of plastic sheet material, such as PS, PP, PVC, PET and ABS

RYZ-750系列全自动液压制杯机是我司开发研制的高速度,高效率的全自动塑料容器的成型机。该机适用于生产PS,PP,PVC,PET,ABS等塑料片材

This equipment adopts five-fulcrum rotary arm structure and is driven by hydraulic system. It is equipped with built-in lubricating system, so it doesn’t have out-lay oil tubing. Its rotary arm is formed by one-off integrated forge. So it features in high operational efficiency, small noise, small vibration, less failure and stable operation, which can efficiently improve the service life and reduce the difficulty on maintenance. Its stretching part adopts hydraulic cylinder, air cylinder, and servo motor, which feature in stable operation, low power consumption and convenient application

该设备采用五支点摆臂结构,使用液压系统驱动,且采用内置式润滑系统,无外置油管,摆臂座使用一体化锻造成型,运行时效率高,噪音小,震感小,故障少,运行稳定。有效提高机械使用寿命及降低维护难度。拉伸部分采用(液压油缸,汽缸,伺服电机),运行稳定,耗电量低,使用方便

This machine adopts PLC system to control: mould travel, mould opening and closing. The pressure of cutting is set on touch screen. The travel of mould can be regulated freely. Mould will not fall off when the machine stops.

该机器采用PLC系统控制模架,模具开关。切割的压力设置在触摸屏上,模架可以自由调节,当模具停止时,模具不会脱落

B. Description 描述

1、Power Supply 380V/3P/50Hz(special voltage available)

电源:380V/3P/50Hz (特殊电压可用)

2、Material: PP/PS/PET/PVC

材料:PP/PS/PET/PVC

3、Driving Method Hydraulic+Pneumatic

驱动方法:液压+空压

4、Running speed 20-35 cycles/min

速度:20-35次/分钟

5、Sheet Width L=750mm(Adjustable)

片材宽度 L=750mm (可调节)

6、Installed Machine Size 7×1.7×2.3m

装机尺寸:Size 7×1.7×2.3米

7、Power Consumption 50-55kw/hr

能量功耗:50-55千瓦/小时

C. Parameter: 参数:

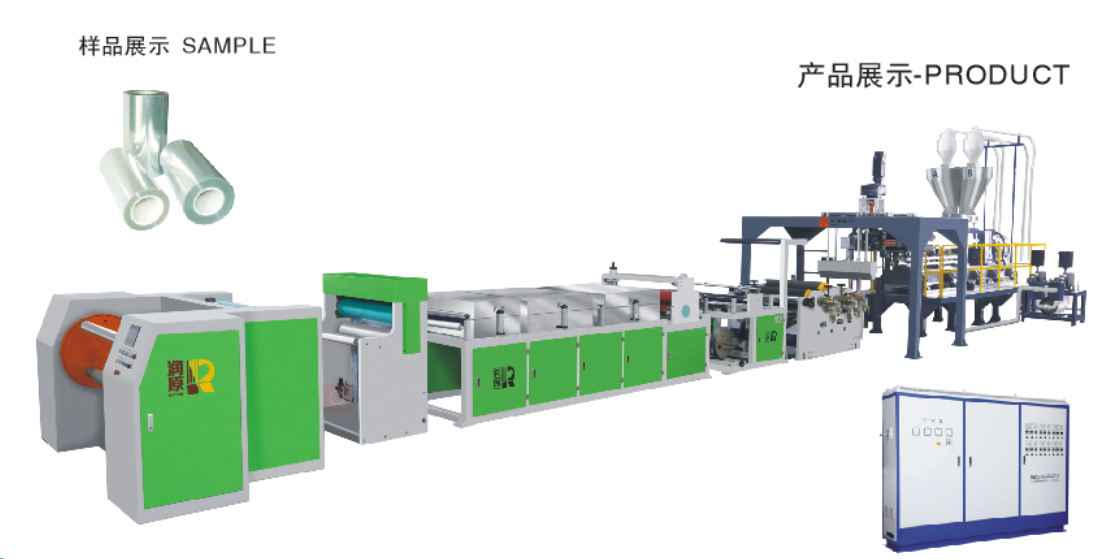

D. Factory Picture: 工厂图片