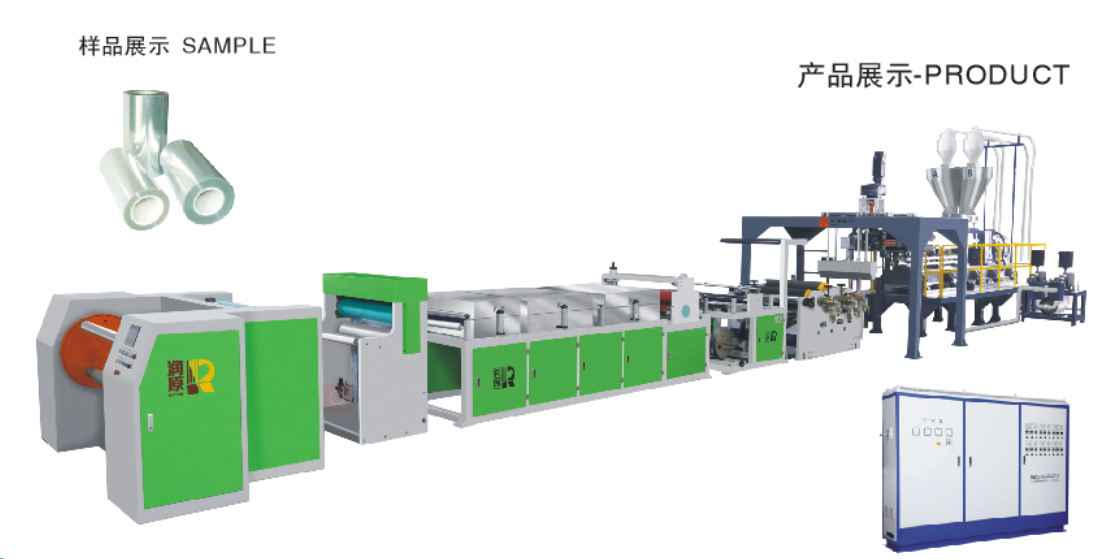

RY-125T-A Automatic Hydraulic Cutting Machine

RY-125T-A自动液压裁剪机

Structural characteristics:结构特点

•Computer control system, touch-screen and simple operation, fast and accurate.

电脑控制系统,触屏式显示屏,操作简单、快捷、准确。

•Hydraulic control system absorbs domestic and foreign advanced technology using energy saving low noise devices.

油压控制系统吸收国内外先进技术,采用节能、省电、低噪音装置。

•Triple fuel tanks, four posts with precise self-balancing to ensure the consistance of each cutting depth.双油缸、精密四柱自动平衡连杠机构、能保证每个裁断位置深度一致。

•Manual hydraulic cutting operation, press the button once to finish one cycle without any disadvantage of imtermittent cutting many time.

油压裁断采用双手动作方式,按扭一次,无连续多次裁断的弊端,设有紧急停止装置,确保操作安全。

•Differential cutting design, die quickly descends, when it moves closing to cut mould then changes to automatic slow cutting, which can eliminate the error between upper and lower layer.

差动设计,快速下降到刀模自动慢切,使工件上层与下层没尺寸误差。

•Eco-friendly materials such as PET, PP, OPS, EPE, ABS will not have rough edges or uncutting edges. It can avoid some waste powder sticking on the food boxes.

在裁环保材料PET、OPS、EPE、ABS时不会有裁不断或边缘毛边。食品盒裁断时可杜绝裁板粉末粘在盒上的现象。

•Cooling system and rotary encoder device make the positioning of knife mold more accurate and stable.

特设有冷却系统和旋转编码器装置,使刀模定位工作更加准确、稳定。

•Cutting power and cutting depth controlled by micromatic setting which can randomly switch to the best cutting pressure and depth quickly. Because of the precision of the balance of cutting, it can greatly reduce the wear and tear of the knife mold and the board.

裁断力、裁断深度设有微调装置,可快速随意获得*之冲裁压力及深度,因裁断平衡度精确,可以极大减少刀模及裁板的损耗。

•Self-lubricating system can ensure the precision of the machine and improve the machine durability.

自动润滑确保机器精密及提高机器耐用度。

•Operator can set unilateral or bilateral automatic continuous mode, improving machine efficient from two to three times in production.

可配合单边或双边自动控制送料装置,令整机生产效率提高两到三倍。

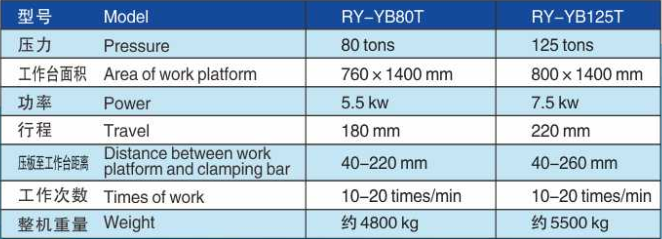

Parameter: 参数